This site uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site you find most interesting and useful.

Bio-decontamination

Surface disinfection through ARECO nebulization

– A patented solution

In disinfection, a liquid biocide is transformed into fine droplets, then dispersed into the air of the areas to be treated to eliminate pathogenic microorganisms, such as spores. Nebulization is thus used in the pharmaceutical industry to uniformly distribute biocidal products.

How does the nebulization disinfection process work?

Nebulization disinfection involves the diffusion of a disinfectant solution in the form of fine microdroplets suspended in the air to eliminate microorganisms present in a space.

The nebulization device disperses a fine mist of microdroplets of a disinfectant solution based on H2O2 (35%). The generated mist consists of 95% of particles smaller than 5 microns, allowing for very rapid evaporation (approximately 0.6 seconds) into the air. These particles are finer than those produced by other high-pressure technologies, allowing them to penetrate through air filters and thus not only treat the decontamination area but also the entire air duct system (ducts, CTA unit, etc.).

The droplets, suspended in the air, spread uniformly throughout the space to be disinfected for complete surface treatment. They reach horizontal, vertical surfaces, and even difficult-to-reach corners. When the saturation point of the environment is reached, a micro-condensation phenomenon occurs. A light liquid film with a high concentration of H2O2 then covers the microorganisms, and after a defined contact time, eliminates them. This phenomenon relies on the fact that H2O2 condenses more rapidly than H2O. To promote this micro-condensation, cooling down the area to be treated may be necessary at the beginning of the cycle, but unlike other bio-decontamination technologies, our system does not require excessive dehumidification of the area to be treated.

Once the disinfection process is completed, ventilation is necessary to remove any excess disinfectant from the air.

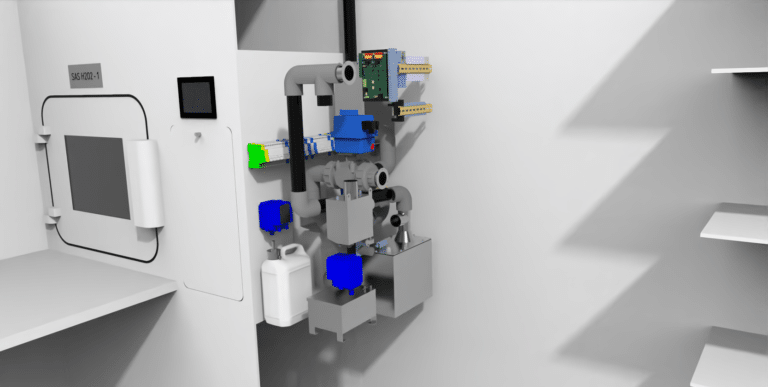

We have developed and patented our own bio-decontamination device. We have chosen to design a surface disinfection system using airborne nebulization technology with cold nebulization of biocides.

Our range of nebulization disinfection solutions is used in sensitive environments such as laboratories, airlocks, isolators, and other places where it is essential to reduce the risk of contamination by pathogenic agents.

In which sectors to use the ARECO bio-decontamination system?

- Pharmaceutical

- Hospital

- Biomedical

- Animal facilities

- Agro-food industry