This site uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site you find most interesting and useful.

Textile Industry

ARECO Nebulization: Your Humidification expert for the Textile Industry

In the textile industry, humidity control is an essential parameter throughout the production chain. Insufficient humidity during weaving can have significant repercussions on both product quality and on workshop efficiency.

Lack of humidity in the air can lead to yarn breakage due to filament breakage or static electricity. It also increased wadding and the risk of defects in the finished product. Additionally, machine downtime can lead to loss of productivity.

It is essential to humidify looms to maintain specific environmental conditions favorable to the weaving process.

Optimize Operation of Industrial Weaving Machines

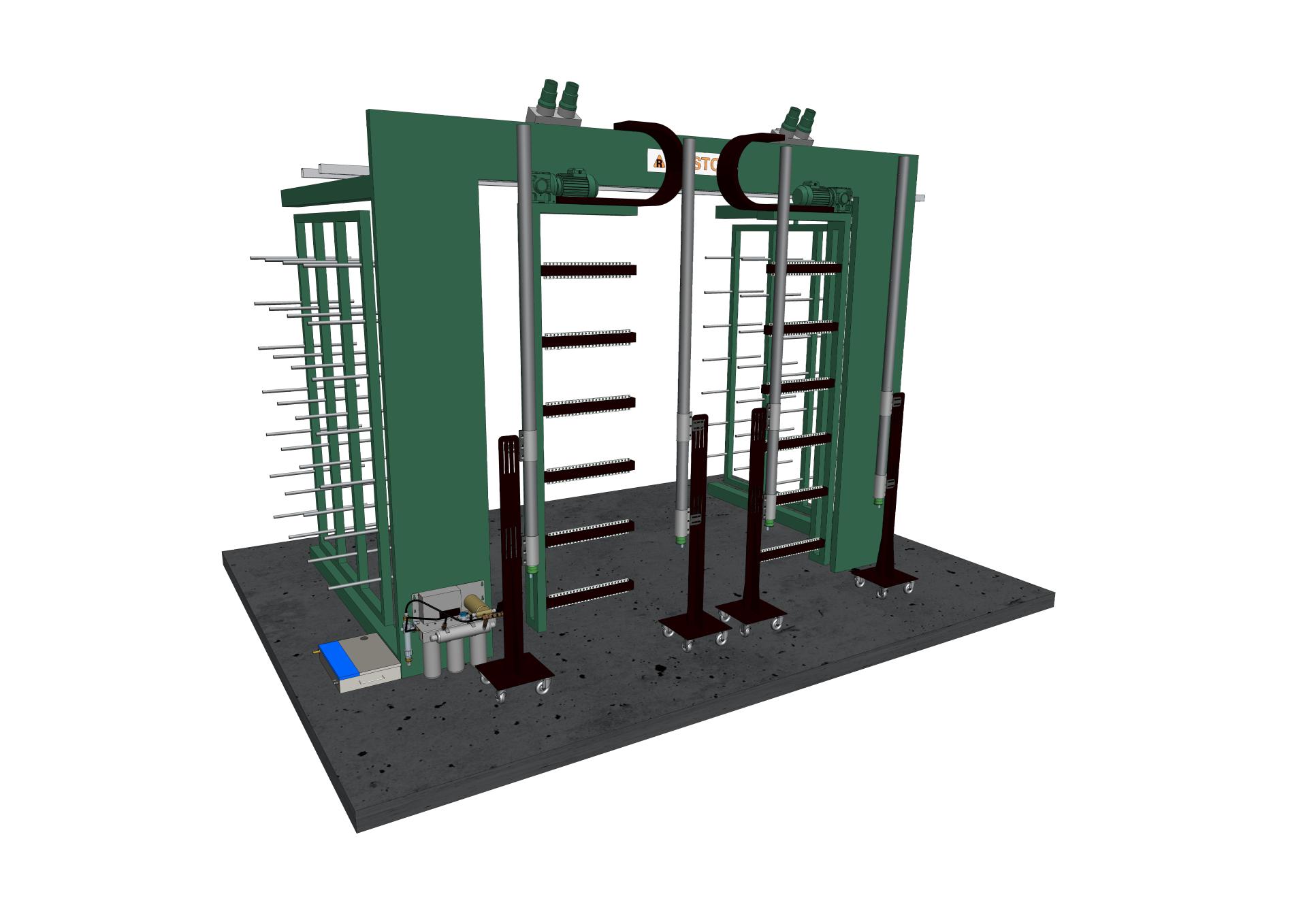

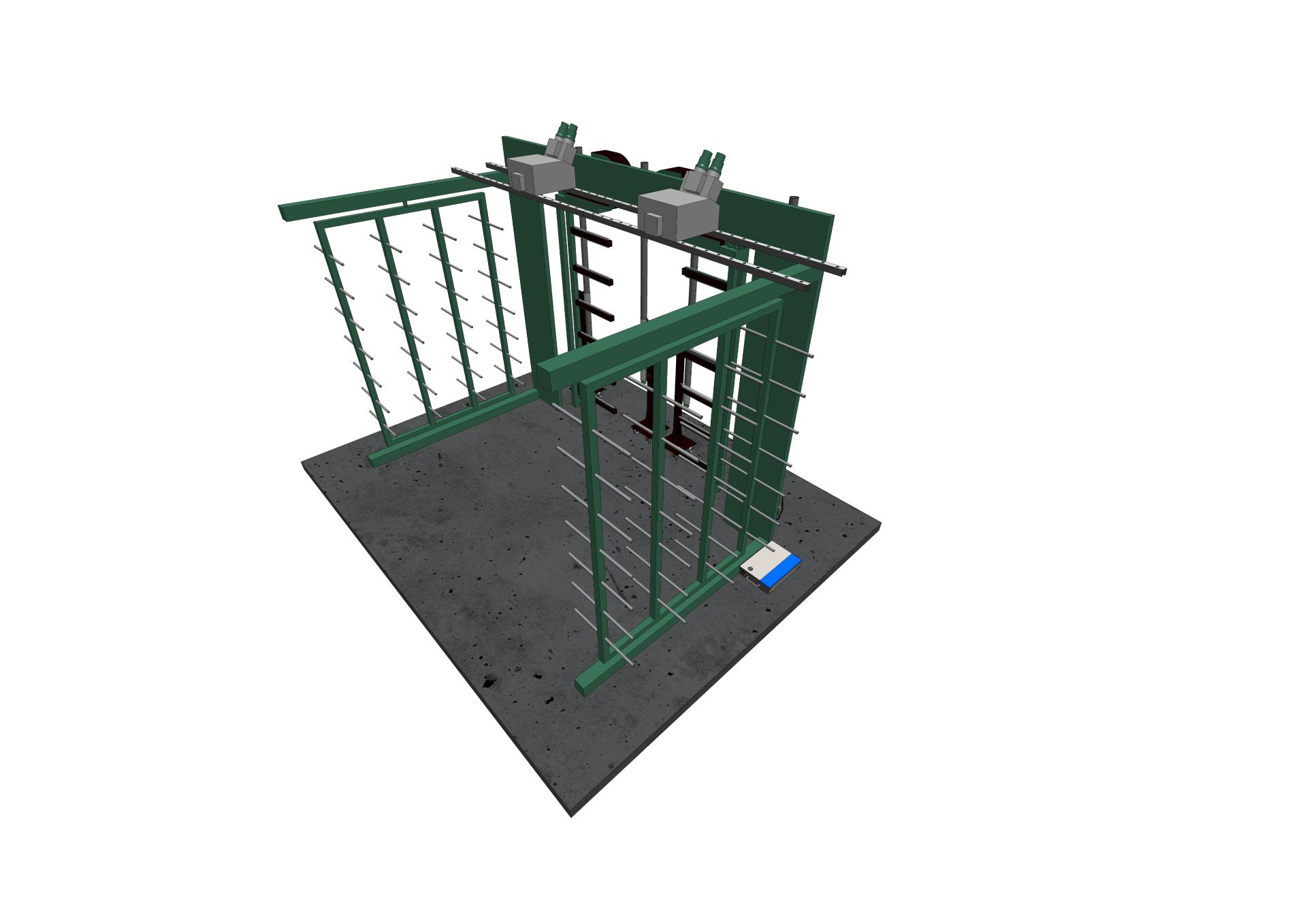

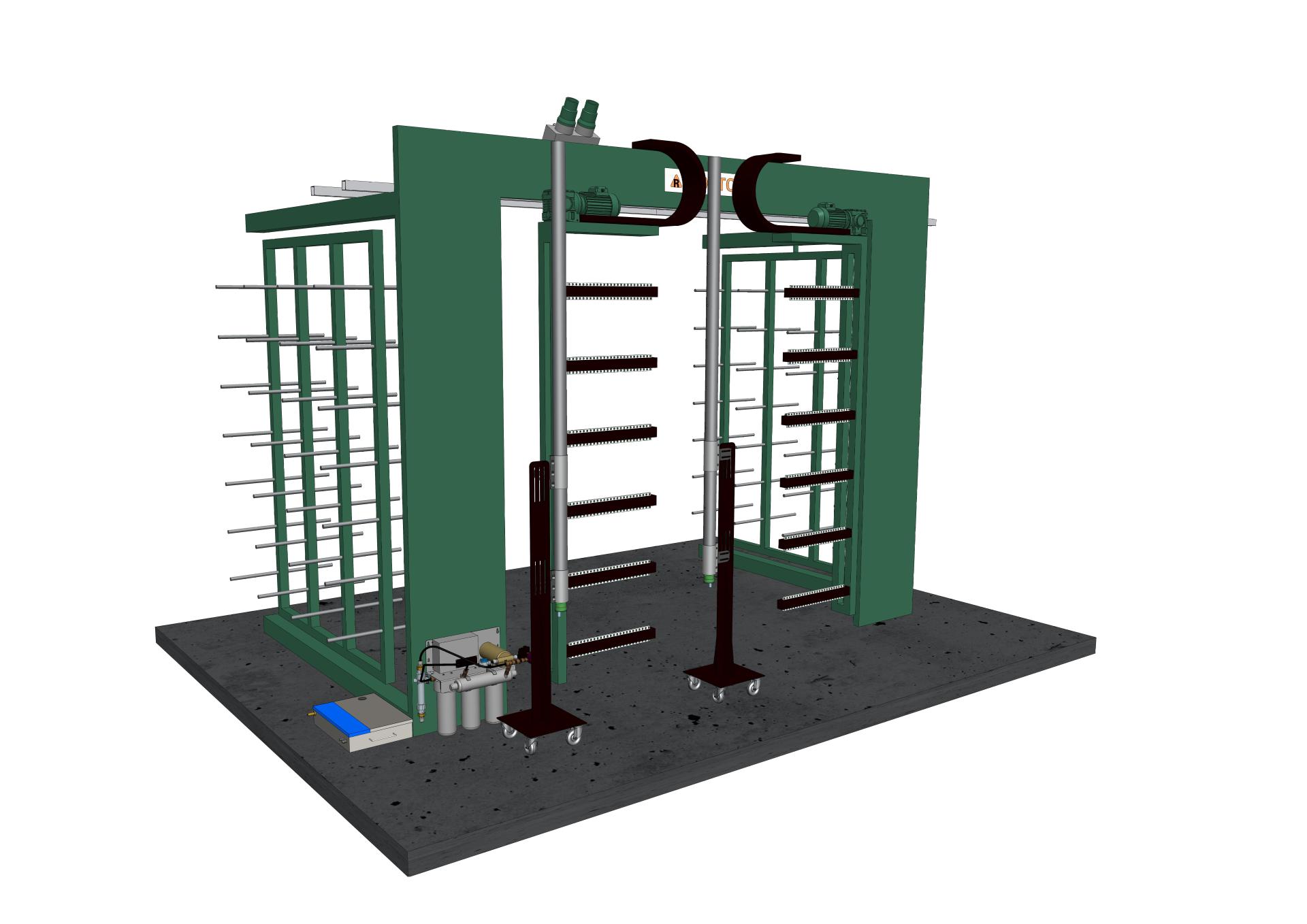

ARECO’s humidification solution for looms is based on a nebulization system. With a droplets size five times smaller than a silk thread, the nebulizer increases hygrometry as close as possible to the looms, without wetting the machines or threads. There is no risk of corrosion or impact on electronics.

The ARECO ultrasonic humidifier reduces yarn breakage, weaving defects and static electricity. It also improves the quantity of material invoiced and consequently your factory’s productivity. Controlling the humidity level ensure top-quality finished products.

Entirely Customized, ARECO humidification for the textile industry adapts perfectly to the operation of each weaving loomEach fiber (cotton, wool, linen, silk…) or filament has its own specific moisture supply.

Moreover, nebulization-based humidification requires less water and electricity than to other products on the market. It is therefore a technology that combines performance and energy saving.

Improve the Weaving Process

ARECO’s humidification systems enhance the weaving process and preserve fiber qualities. The major advantage of our technology lies in managing humidity as close as possible to the loom, unlike ambient management systems. This allows:

- Ensuring precise humidity levels in proximity, avoiding homogeneity issues common in ambient systems.

- Independently regulating humidity on each loom, enabling the processing of multiple materials in the same workshop.

Advantages of Nebulization Humidification:

- Guarantee precise humidity levels as close as possible, avoid the problems of homogeneity encountered with ambient systems.

- Independently regulate the humidity level on each loom, allowing work with various types of materials in the same workshop.

- Relative humidity control: Textile fibers, especially cotton, linen and wool threads, are sensitive to ambient humidity. Excessively dry conditions can lead to fiber dehydration, making them more fragile and susceptible to breakage during the weaving process. Humidification maintains the right relative humidity to prevent these issues.

- Avoid static electricity: In very dry conditions, static electricity can accumulate on threads and fibers, leading to interference in the weaving process and irregularities in the finished product.

- Improved fabric quality: Humidification contributes to better fiber cohesion during the weaving process, resulting in improved fabric quality. It also aids in the reduction of imperfections and irregularities in the final fabric. Quality improvement is largely linked to a reduction in the breakage rate, because each breakage of thread requires a knot to be made, which deteriorates fabric quality.

- Facilitating the weaving process: Adequate humidity makes fibers more flexible and easier to handle during the weaving process, facilitating the work of looms.

- Maintaining operator comfort: by adjusting humidity in the environment close to the loom, ARECO nebulization avoids excessive increases in humidity throughout the workshop. This is unlike climate control systems which, for certain materials like cotton or linen, need to raise the entire workshop to over 80% RH.

Improve the Warping Process

Warping is a crucial step in the process of preparing threads before weaving. The use of humidification during warping brings several advantages:

- Reduced Thread Breakage: Threads used in weaving can be fragile, especially if they are thin. Humidification during warping makes these threads more flexible and less prone to breakage, improving the efficiency and quality of the process.

- Avoid Static Electricity: As in the weaving process, static electricity can be generated during warping, especially in dry environments. Humidification helps to minimize the build-up of static electricity, preventing the “ballooning” effect, i.e., preventing the threads from pulling apart.

- Maintaining Thread Stability: When threads are humidified, they are more stable, which is particularly important for preventing thread deformation during warping.

- Facilitating the Warping Process: Humidified threads are easier to handle, simplifying the process and reducing the risks of knots or thread breakage.

- Improving Fabric Quality: By ensuring that threads are in optimal conditions before weaving, humidification during warping contributes to producing a better quality fabric with fewer imperfections.

Because every warping workshop is different, we design all our humidification systems to order. Our humidifiers integrate seamlessly and discreetly into your machines.

With nebulization humidification, you benefit from a technology that is low in water and electricity consumption. In this way, from other products available on the market.

Improve the Spinning Process

Spinning involves transforming raw fibers into yarn. Humidification during the spinning phase has a number advantages:

- Reduced Fiber Breakage: Raw fibers can be dry and fragile. Humidification helps to make fibers more flexible, reducing the risk of breakage during the spinning process. This improves process efficiency by minimizing interruptions due to fiber breakage.

- Facilitates Carding: Carding is often a stage in spinning process where fibers are disentangled and aligned before being spun. Humidification facilitates carding by making fibers more pliable, thus facilitating combing and correct fiber alignment.

- Dust Control: Raw fibers can produce dust during spinning. Humidification minimizes dust, making the atmosphere more pleasant for operators.

- Improved Yarn Quality: Humidifying fibers results in higher-quality yarns. Humidification contributes to a more uniform transformation of the fibers into yarns, thus reducing potential imperfections in the final product.

- Prevention of Static Electricity: As in other stages, static electricity can be generated during spinning, especially if the air is dry. Humidification reduces static electricity, which limits fiber entanglement and yarn breakage.

Improve the Productivity of Your Establishment

In textile production workshops, temperatures can be high. The continuous operation of the machines generates intense heat, causing discomfort and a health risk for employees.

Misting these area has a number of benefits that will boost your plant’s workshop:

- Humidity Control: Misting maintains an optimal humidity level in the workshop.

- Dust Reduction: Misting helps to control the dust generated by the various stages of textile production, which is crucial for maintaining a clean and healthy working environment, while preventing dust from interfering with machines and finished products.

- Temperature Control: The diffusion of fine water droplets in the air helps to regulate ambient temperature and has a cooling effect.

- Static Electricity reduction: Misting reduces static electricity, a common issue in dry environments.