This site uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site you find most interesting and useful.

ARECO Industry: expert in fluid management expertise for industrial performance

Our expertise

In the industrial sector, where fluid management is essential, whether it’s controlling humidity in various areas or ensuring pharmaceutical decontamination, ARECO Industry has positioned itself as an expert for 26 years.

Whether in textiles, agri-food, or other fields, maintaining optimal humidity levels is crucial to ensure efficient manufacturing processes and safe working conditions. By closely monitoring relative humidity, companies can prevent equipment, raw materials, and finished products from deteriorating while optimizing their production processes.

In the pharmaceutical industry, where preventing infectious risks is of paramount importance, airborne surface disinfection (ASD) plays a crucial role. The bio-decontamination process developed by ARECO is a real asset for effectively treating surfaces and meets the demanding standards of this sector.

By investing in fluid management solutions like those offered by ARECO Industry, companies in various sectors can increase their return on investment (ROI) while ensuring the performance, durability, and compliance of their industrial operations.

Humidification

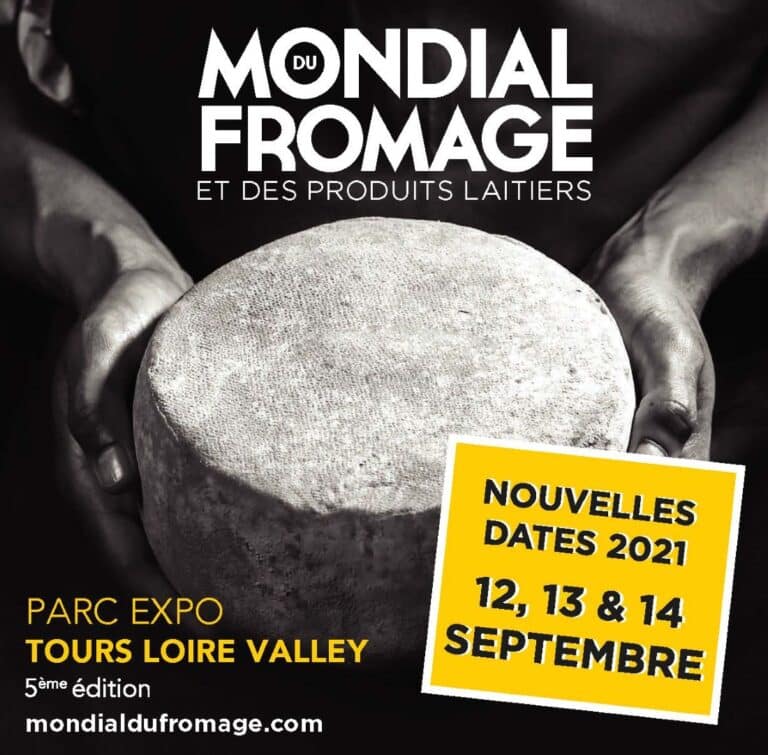

Explore how misting and fogging enhance productivity in environments such as laboratories, cheese dairies, wine cellars, weaving mills, and much more.

Bio-decontamination

Discover our expertise in bio-decontamination, deployed in controlled atmosphere zones, cleanrooms, airlocks, isolators and gloveboxes.

Custom Industrial Solutions

Our results, backed up by figures, confirm the positive impact of our solutions.

Our commitment to excellence translates into measurable performance.

Discover how our expertise can enhance your results.

Would you like more information about your project?

CONTACT US

Our international presence

ARECO Industry proudly asserts a global footprint with nearly 10,000 installations spanning across the entire world.

They trust us

We build lasting relationships with our customers. They are much more than just business partners to us; they are true partners. Our customers testify and share their experiences of using our humidification and bio-decontamination solutions.