This site uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site you find most interesting and useful.

Wine Industry

ARECO Nebulization: A versatile technology for all aspects of winemaking

ARECO Nebulization: A versatile technology for all aspects of winemaking

The hygrometric conditions of a wine cellar are crucial for preserving the taste, texture, and quality of wines and spirits, as well as reducing losses due to evaporation, known as the angel’s share.

Master the quality of your winemaking industry.

ARECO nebulization, applied to the wine market, maintains optimum hygrometric conditions to meet all these criteria.

Where does ARECO nebulization technology apply in winemaking?

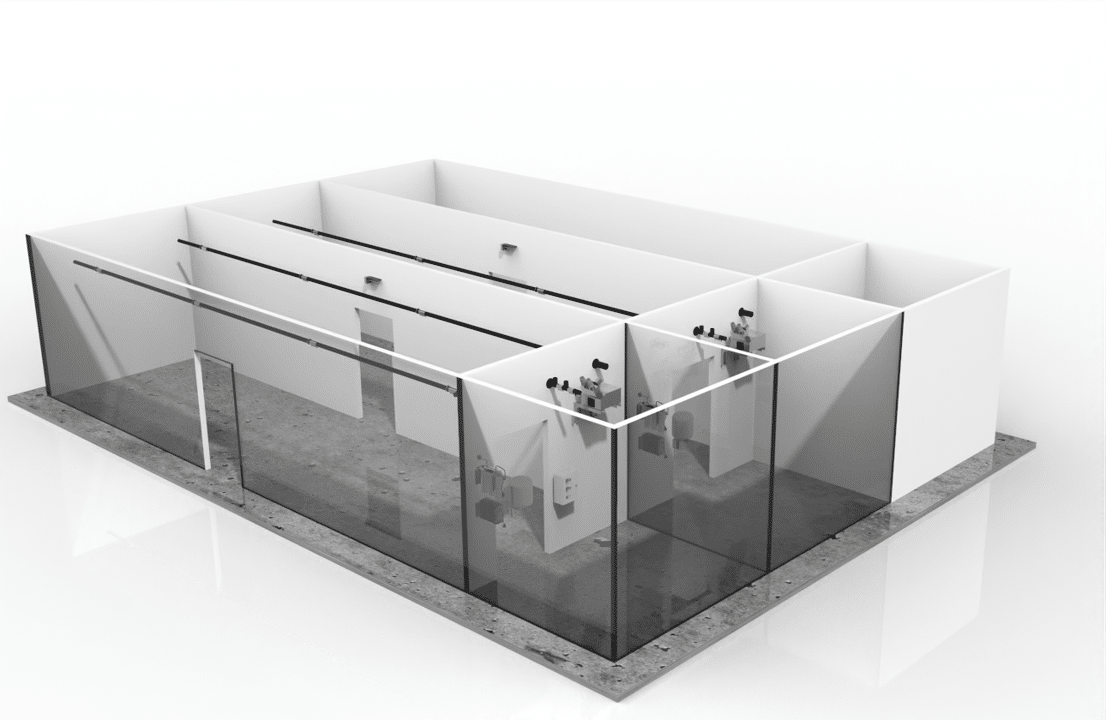

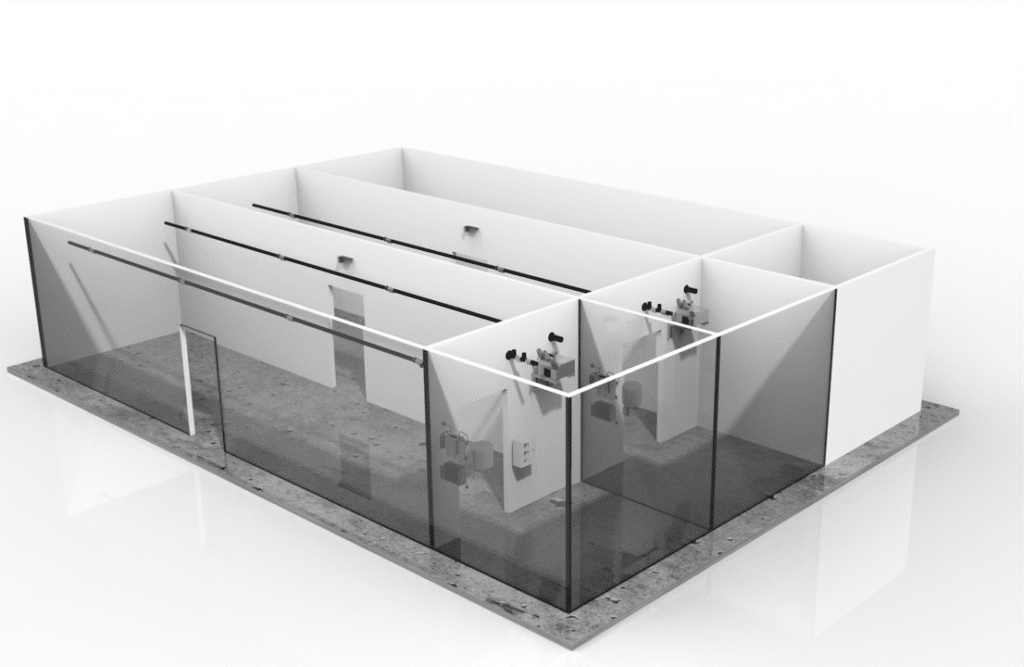

- Barrel/tank cellars: wine-making control, controlled consumption

- Bottle cellars: preservation, label and cork quality

- Cork manufacturing: storage in dry regions (e.g., Chile)

- Cooperage: storage

- Storage of labels and cartons

- Cutting and grafts nursery

Concrete Cases of Return on Investment #1

Nebulization of a 100-barrel cellar with a selling price per liter of €10 generates sales of €5,620/year due to the reduction in wine evaporation.

Return on Investment: 2 years

ARECO nebulization reduces evaporation losses by controlling the humidity level. Consequently, it allows control of taste diversity and alcohol content.

Advantages of ARECO Nebulization:

- Control of humidity levels

- Improved preservation of wine quality

- No deposit or mold formation on barrels

- Consumption (Angel’s share) divided by 2

Concrete Cases of Return on Investment #2

Nebulization of a cellar with 3000-barrels winery with a €10/liter selling prince generated €300,000/year in sales by reducing alcohol consumption.

Return on Investment: 2 months