This site uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site you find most interesting and useful.

Cheese Industry

ARECO Nebulization: Your Humidification Expert for Cheese dairies

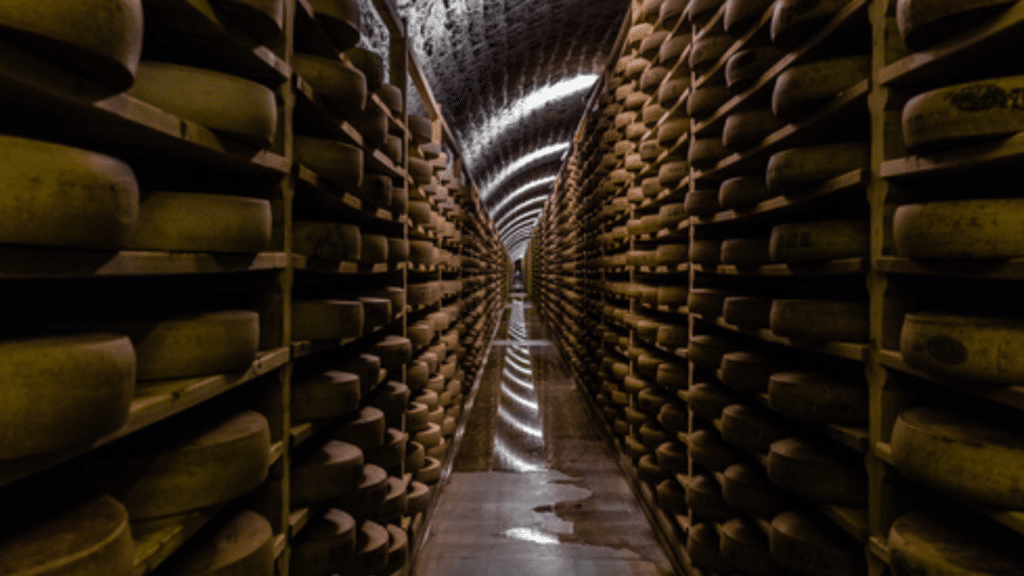

In cheese cellars, controlling humidity is crucial to ensure the product production and ripening. Poor humidity levels can directly impact final product quality.

Artisanal cheesemakers and manufacturers must deal with the phenomenon of product drying out and shrinkage. Also, the visual aspect of cheeses can deteriorate.

For over 26 years, the ARECO team has developed humidification solutions for cheese dairies. These innovative and efficient solutions help producers improve cheese maturation.

Whatever the surface area of your cellar or ripening room, our team will offer you a customized, made-to-measure solution.

Control Humidity Levels in Cheese Cellars

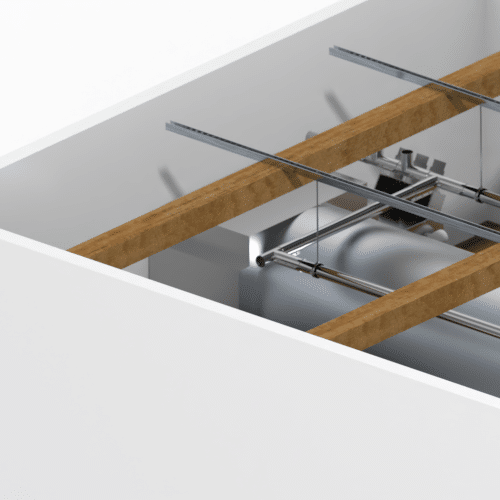

With the ARECO nebulization solution, artisan cheesemakers and manufacturers can control hygrometry with static or dynamic cooling, right up to saturation.

A probe installed in the storage or maturing room allows very fine regulation of humidity in the cellar.

As a result, products no longer dry out in the ripening room.

This solution has convinced many professionals in the cheese-making industry to sustainably preserve product quality.

Improve the Cheese ripening Process

ARECO humidification systems improve the maturing process and preserve the organoleptic qualities of cheeses.

Benefits of nebulization humidification:

- Maintaining optimal humidity throughout the production and sales chain.

- Reduced shrinkage (weight loss divided by 2) through humidity control.

- Production control to maintain cheese quality (fat content, crusting, development of flora, etc.).

- Better production uniformity due to homogeneous humidity throughout the cellar.

- Improvement visual appearance: stickiness, texture, crusting.

- Protection against flies and mites with controlled humidity.

26 Years of History with Our Customers

We are an artisan company specializing in the maturing of Savoie farmhouse cheeses. We have 15 cheese cellars equipped with ARECO nebulizers. These devices allow us to supplement the relative humidity in our cellars. This humidity is crucial to the proper processing of our cheeses : even mold development, reduced weight loss. Today, it seems unthinkable for us to work without this additional humidity.

Bertrand Paccard and Joseph Paccard

Seeding Cheese cellars

As a partner to cheese-makers, the ARECO team is continually developing new solutions to meet production needs.

During cheese production, lactic ferments are particularly important. They are incorporated into the products before the maturation process.

However, for certain cheeses, they need to be re-inoculated during the ripening process.

Faced with this need, the ARECO team has developed a solution for seeding atmospheres by nebulization. The process, develop with ENILBIO in Poligny, is fully automated and mobile. This humidification solution can be used simultaneously in several cheese cellars.

Unlike existing systems on the market, nebulization treats a volume rather than a surface. The ferments used for ripening (Geotrichum, Brevibacterium, Debaryomyces, Penicillium, etc.) are evenly and optimally distributed throughout the cheese cellar.

The nebulization seeding process contributes to better control of the cheese maturation process. It improves the overall quality of the production process, as well as the long-term stability of the cheese.

With this process, the ARECO team offers another innovative and efficient cheese humidification solution for master cheese ripeners.

Humidification of Creamery maturing cellar

Many creameries have their own ripening cellars to complement the sales area. As in cheese dairies, humidity regulation is an essential parameter.

The ARECO humidification system provides optimum conditions for preserving cheeses before they go on sale. The fine regulation of humidity greatly reduces product shrinkage and the risk of cracking.

With this technology, you can offer your customers better quality products.

Our solution also enables you to refine cheeses purchased from other producers. This is particularly useful for long-aging cheeses. You can buy these cheeses at a less advanced stage of ripening mature stage (e.g., young Comté) and thus achieve a better purchase price.

As a result, the profitability of your creamery is significantly improved.

Concrete Return on Investment Case

For a production of 233 tons of cheese at €7.5/kg, which would be subject to 6% shrinkage, nebulization reduces weight loss by 50%. This represents a saving of €52,000/year.

Non-contractual example